Product Display

Features Summary

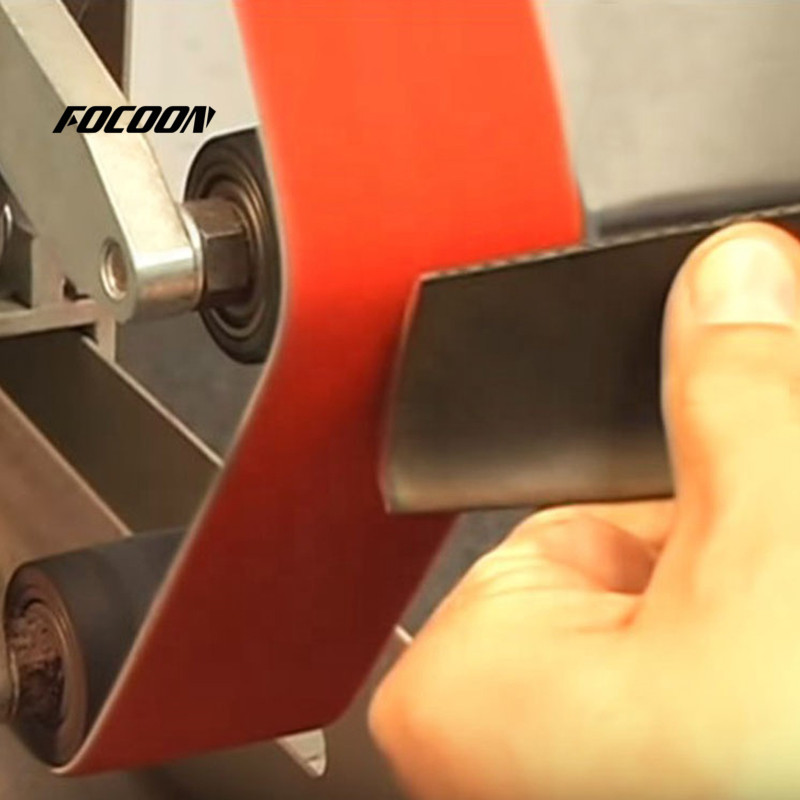

High strength, good heat resistance, sharp cutting, high grinding efficiency, not easy to generate heat and blockage during the grinding process, and small thermal expansion to control the machining accuracy. Suitable for high-performance grinding, but also for economical grinding of forgings, blanks and castings. High cutting rate: good self-sharpening, can ensure faster grinding speed, shorten the time of processing the workpiece, and ensure better surface processing quality and removal rate; Cold grinding: grinding aids are added to the surface, the grinding temperature is low, and the heat is low, which can extend the working life, prevent the surface from burns and discoloration, and effectively ensure the surface quality of the polished workpiece. The strength of the backing is extremely high, supporting light/medium/heavy load grinding, and can be dry or wet grinding; Applicable materials: stainless steel, carbon steel, tool steel, hard chromium steel, hard cast iron, high alloy steel, high chromium alloy, titanium alloy, chromium-nickel alloy, nickel-based alloy, cobalt-based alloy and superhard materials, etc. Examples of workpieces: radiators, radiators, turbine blades, tools, metal coils and plates, steel pipes, tanks, bathroom accesories, castings, medical equipment, construction hardware, etc. Applicable equipment: fixed and hand-held abrasive belt grinders, grinding robot systems.Imported glue. multiple processing The Joint is flat and not easy to break High toughness value and good cutting performance

Good heat dissipation Continuously produce new cutting edges Long service life and good resultsHigh quality abrasive, full sand Sharp and durable, not easy to lose sand High cost performance

Good heat dissipation Continuously produce new cutting edges Long service life and good resultsHigh quality abrasive, full sand Sharp and durable, not easy to lose sand High cost performance

Product Advantage

Ceramic Abrasive Belt The unique sand planting technology is used to make the sharp corners of these ceramic alumina ore with precise shapes face upwards when coating, like countless sharp triangular blades. Therefore, its grinding process is more like cutting, easily removing the metal and taking away the heat with the metal shavings. This method can prevent heat from accumulating in the workpiece, thereby effectively avoiding cracks and burns to the workpiece due to thermal stress. Moreover, this triangular-structured ceramic alumina particles are sintered from a large number of alumina microcrystals, which can continuously break and form new sharp corners and sharp edges under certain grinding pressure. Grinding force can be maintained well. This kind of maintenance of "cold cutting" and continuous sharp grinding state makes the grinding tools have higher grinding efficiency and longer service life, making the grinding process easier. Good heat dissipation Continuously produce new cutting edges Long service life and good results

Good heat dissipation Continuously produce new cutting edges Long service life and good results

Product Advantage

High quality abrasive, full sand Sharp and durable, not easy to lose sand High cost performance

Wearable

Fast heat dissipation

Not Easy To Lose Sand

Professional Manufacturer

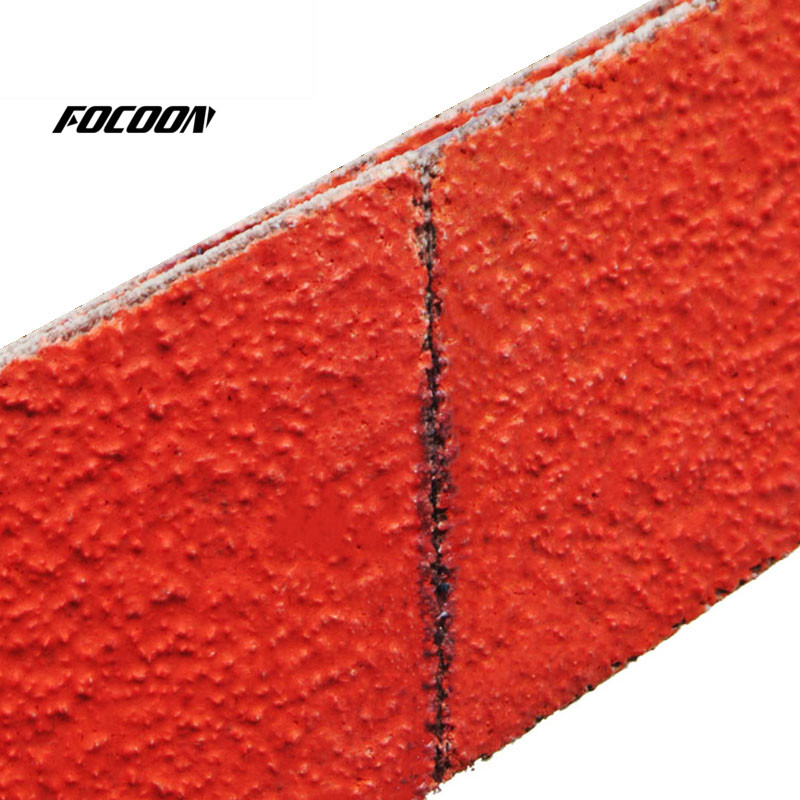

Imported glue. multiple processing The Joint is flat and not easy to break High toughness value and good cutting performance

Imported glue. multiple processing The Joint is flat and not easy to break High toughness value and good cutting performance