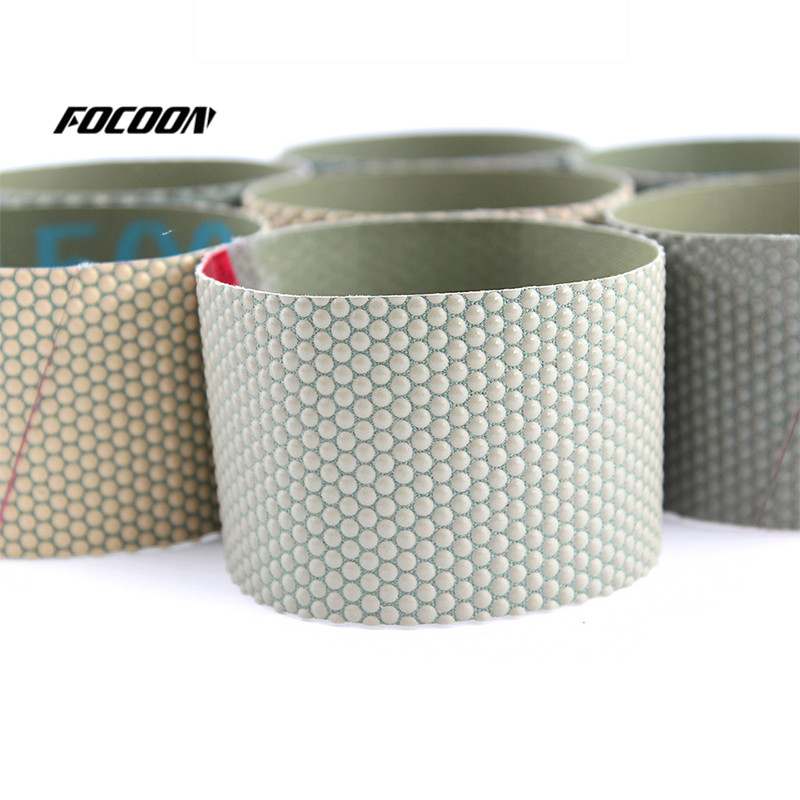

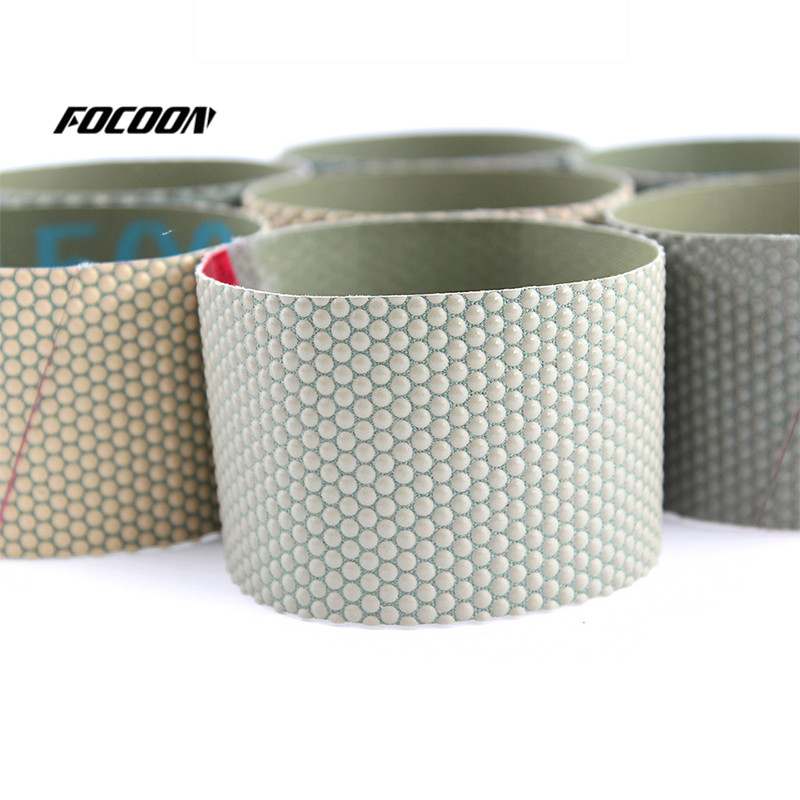

Product Display

Specification

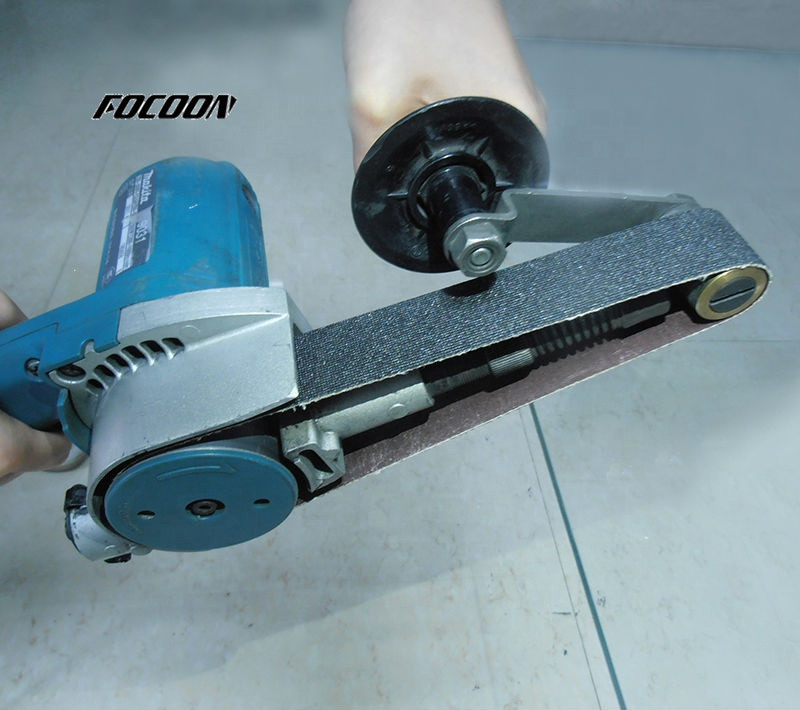

Usage

Diamond abrasive belts are divided into three categories according to usage, tool performance, and manufacturing difficulty: (1) Resin dispensing type abrasive belt Resin dispensing type, its manufacturing equipment is simpler than coating type products, the equipment investment is lower, and the dispensing type can improve the shortcomings of resin coating products, because ordinary resins are more brittle and hard and have poor flexibility after curing. In addition, the dispensing type products have evenly distributed gaps in the middle, so they can perform better grinding performance when grinding hard plastic materials or during dry grinding. (2) Resin full-coated abrasive belt This type of abrasive belt is to uniformly coat the resin on the entire substrate surface, so that the abrasive is distributed on the entire surface of the cloth base with a certain density. This type of abrasive belt manufacturing method has manual coating type and mechanical coating type. Due to the long service life and small production scale of diamond abrasive belts, in order to reduce equipment costs, manual coating or semi-manual and semi-mechanical manufacturing processes can be adopted when there is no requirement for performance. The manual coating process cannot control the coating uniformity of abrasives and binders, and the production process is not continuous, resulting in uneven working surface thickness of the abrasive belt, uneven distribution of abrasives, and uneven orientation of abrasives, resulting in low product quality; (3) Electroplating abrasive belt Electroplating abrasive belt is a common type produced by domestic and foreign manufacturers, mainly due to the simple production equipment of electroplating sand belt, and the high bonding strength of the electroplating abrasive belt, the wear resistance and temperature resistance of the adhesive are higher than that of resin. However, problems such as the strength of the electroplated closed abrasive belt substrate and the strength of the substrate joint need to be further studied and resolved.Although price higher than conventional belt Due to the long life High cost-effective than conventional belt

Enhance the corrosion resistance of metals Increase hardness, prevent wear Improve smoothness, and heat resistanceStrong flexibility, good elasticity Not easy to wrinkle Not easy to break

Enhance the corrosion resistance of metals Increase hardness, prevent wear Improve smoothness, and heat resistanceStrong flexibility, good elasticity Not easy to wrinkle Not easy to break

More efficient

Manufacturer

Professional Manufacturer

More effortless

Product Advantage

Enhance the corrosion resistance of metals Increase hardness, prevent wear Improve smoothness, and heat resistance

Product Advantage

Strong flexibility, good elasticity Not easy to wrinkle Not easy to break

Although price higher than conventional belt Due to the long life High cost-effective than conventional belt

Although price higher than conventional belt Due to the long life High cost-effective than conventional belt